How to Use Weld Truck Flatbed Drawings PDF for Custom Builds

Weld truck flatbed drawings PDF are essential for anyone planning to build or customize their own flatbed truck. These detailed drawings guide the construction process, ensuring precision in dimensions and materials. Using these PDFs makes the project easier by providing a visual roadmap, helping you avoid costly mistakes. In this article, we’ll explore how to create and use weld truck flatbed drawings PDF, the advantages of using them, and tips for ensuring a smooth build.

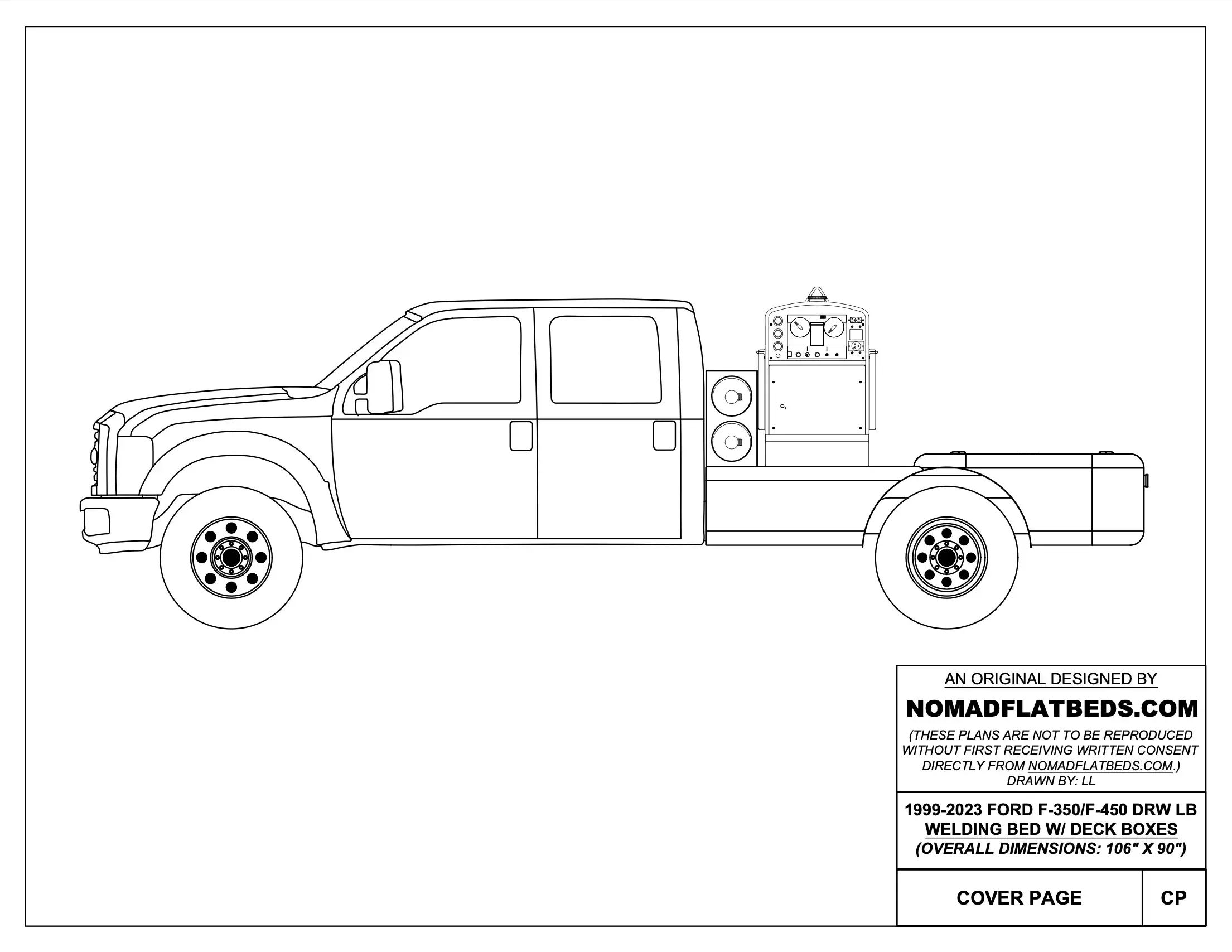

1. Why Weld Truck Flatbed Drawings Are Important

Weld truck flatbed drawings are blueprints that show the specific dimensions and materials required to build or modify a truck’s flatbed. They provide the exact measurements for welding, cutting, and assembling parts. Without these drawings, it can be challenging to ensure accuracy, which could lead to misalignments or structural issues.

2. How to Access Weld Truck Flatbed Drawings PDF

2.1. Downloading Pre-Made Drawings

There are many pre-made weld truck flatbed drawings available online. These can be downloaded in PDF format, saving you the time of creating your own. Make sure the PDF file includes all necessary dimensions and material lists. This will make it easier to follow during the build process.

2.2. Customizing Your Own Drawings

If you’re building a flatbed with specific requirements, you may need to create your own drawings. Software like AutoCAD or SketchUp is commonly used for designing weld truck flatbeds. These programs allow you to draw to scale and export the design as a PDF for easy reference.

3. Key Elements in Weld Truck Flatbed Drawings PDF

3.1. Dimensions and Scale

One of the most important elements of a weld truck flatbed drawing is the accurate dimensions. Every part of the flatbed, from the length and width to the height of the side rails, needs to be drawn to scale. This ensures that the materials fit together properly during assembly.

3.2. Material Specifications

The PDF should include a detailed material list, specifying what type of steel, aluminum, or other materials are required. Material thickness, grade, and size should all be clearly indicated to avoid confusion during the purchasing process.

3.3. Welding Details

Your weld truck flatbed drawings should include information on where and how the materials will be welded. This includes weld types, such as fillet or butt welds, and their locations on the flatbed structure. Including this information ensures the flatbed is strong and durable.

4. Understanding Welding Techniques for Flatbeds

4.1. Types of Welding Used

For flatbed construction, common welding techniques include MIG (Metal Inert Gas) welding and TIG (Tungsten Inert Gas) welding. MIG welding is typically used for heavier steel components, while TIG welding is used for more delicate or thinner materials. Each weld truck flatbed drawing PDF should indicate the appropriate welding method for each part of the build.

4.2. Safety Considerations

When working with welding equipment, safety is a top priority. Always wear protective gear such as helmets, gloves, and fire-resistant clothing. The drawings should indicate proper ventilation areas or places where extra safety precautions are required.

5. Step-by-Step Process for Using Weld Truck Flatbed Drawings PDF

5.1. Preparing Your Workspace

Before beginning your flatbed build, make sure your workspace is well-organized. Have all necessary materials on hand, including the PDF file open on a nearby device for reference. Organizing your tools and materials will save time and reduce errors during the welding process.

5.2. Measuring and Cutting

Follow the dimensions in the weld truck flatbed drawings PDF carefully. Begin by measuring and cutting the materials to size. Accurate cuts are essential for a smooth assembly, so double-check measurements before cutting.

5.3. Assembling the Flatbed Frame

Once the materials are cut, start assembling the frame. Use clamps to hold pieces in place before welding. Follow the welding details in the PDF to join the materials correctly.

5.4. Final Welds and Reinforcements

After the frame is assembled, go over the entire structure and add any necessary reinforcements. This could include additional welds in high-stress areas or adding braces for extra support. These details should be clearly indicated in the PDF drawing.

6. Customizing Your Weld Truck Flatbed

6.1. Adding Functional Features

You can customize your flatbed to suit your needs. Weld truck flatbed drawings PDF often include options for adding toolboxes, side rails, or tie-down points. If not, these can be added by adjusting the drawings or adding supplementary PDFs with the custom designs.

6.2. Adjusting for Different Vehicles

Flatbeds can be adapted to fit different truck models. Ensure your weld truck flatbed drawings PDF account for the specific dimensions of your vehicle, including the wheelbase, suspension height, and overall length.

7. Common Mistakes to Avoid

7.1. Ignoring the Drawing Details

One of the most common mistakes is not following the weld truck flatbed drawings PDF closely enough. Every measurement and instruction is there for a reason. Skipping over details can result in poor alignment or weak structural integrity.

7.2. Using Incorrect Materials

Always use the materials specified in the drawing. Substituting materials can compromise the strength and durability of the flatbed. For example, using thinner metal than specified could lead to a weaker structure.

8. Finding Additional Resources for Weld Truck Flatbed Drawings PDF

8.1. Online Communities

There are many online forums and communities where you can find additional weld truck flatbed drawings in PDF format. Joining these communities can also provide you with valuable tips and tricks from experienced welders.

8.2. Professional Services

If you’re unsure about creating or interpreting your own weld truck flatbed drawings, professional services can help. Many companies specialize in designing custom flatbed drawings for specific trucks, and they can provide a detailed PDF tailored to your needs.

10. Future Trends in Weld Truck Flatbed Design

10.1. Advancements in Welding Technology

Welding technology is constantly improving, making it easier to create precise and durable flatbeds. As more advanced welding tools become available, the quality and complexity of weld truck flatbed drawings PDF will continue to evolve.

10.2. Sustainable Materials in Flatbed Construction

Sustainability is becoming more important in construction, and truck flatbeds are no exception. Future weld truck flatbed drawings may include options for using eco-friendly materials, such as recycled steel or lighter-weight alternatives that reduce fuel consumption.

11. Conclusion

Weld truck flatbed drawings PDF are essential tools for anyone planning to build or customize a truck flatbed. These drawings provide the detailed instructions needed for accurate welding, cutting, and assembly. Whether you’re using pre-made PDFs or creating your own custom designs, following these drawings closely ensures that your flatbed will be both durable and functional. With proper planning and attention to detail, you can create a high-quality flatbed that meets all of your specific needs.